The Plastic Tubing Guide

If you’re looking for a durable, lightweight, and affordable material for your next project, plastic tubing is a great option. But with so many different types of plastic tubing on the market, it can be hard to know where to start.

In this guide, we’ll cover everything you need to know about plastic tubing, from what it is and how it’s made to the different types that are available.

What Is Plastic Tubing?

Plastic tubing is a type of tubing made from a polymer and a variety of chemicals to create a material that can be rigid or flexible. Plastic tubing is made by combining materials in any wall thickness, diameter, tolerance, and strength to suit specific applications.

When plastic extrusions are being made, there are a number of considerations that need to be taken into account in order to create the perfect product. These include the type of plastic being used, the size and shape of the tubing, and the color of the plastic tubing. All of these factors will play a role in determining the final product.

Here are a few things to keep in mind when it comes to the tubing extrusion process:

The type of material you’re working with

The type of plastic being used is important because it will determine the properties of the tubing. The most common type of plastic used for tubing extrusion is PVC, but there are also other options such as polyethylene and polypropylene. Each type of plastic has its own advantages and disadvantages, so it’s important to choose the right one for the job.

The size and shape of the tube

The size and shape of the tubing are also important. The most common shapes are round, oval, and square, but there are also other options such as rectangular or triangular. The size of the tubing will be determined by the intended use of the product. For example, if the tubing is going to be used for plumbing, it will need to be a certain size in order to fit mating couplets.

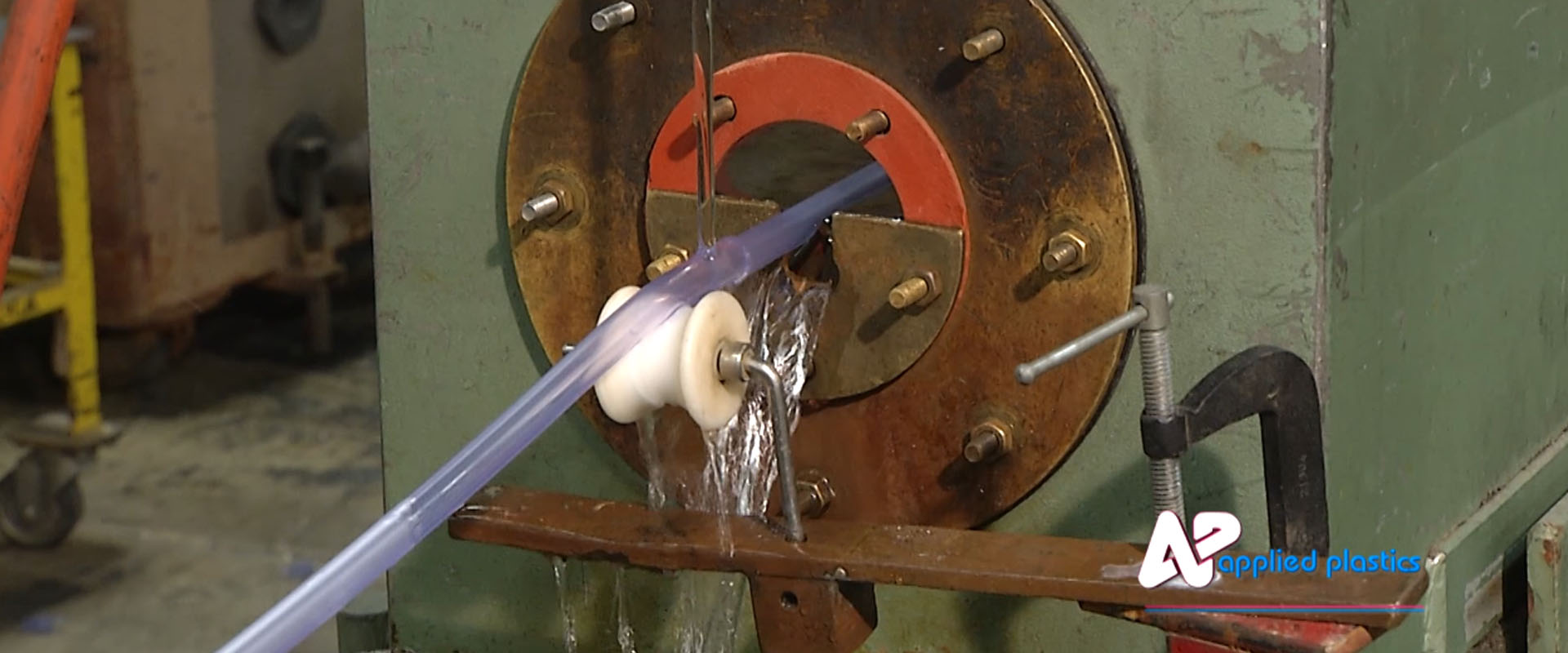

The die is used for the tubing extrusion process

The color of the plastic tubing is also a consideration that needs to be made. The most common colors are white, black, and clear, but there are also other options such as green, blue, and red. The color of plastic tubing will be determined by the intended use of the product. For example, if the tubing is going to be used for electrical wiring, it will need to be a certain color in order to be visible.

The speed and pressure at which the tube is being extruded

The speed and pressure at which the tubing is extruded will also play a role in the final product. The extrusion process can be done at different speeds and with different levels of pressure, depending on the desired result. For example, if the tubing is going to be used for plumbing, it will need to be extruded at a higher speed and with more pressure in order to create a tight seal. Conversely, if the tubing is going to be used for electrical wiring, it will need to be extruded at a slower speed and with less pressure in order to avoid damaging the wire.

By taking all of these factors into consideration, you can be sure that you’re creating the perfect product for your needs.

Why Choose Applied Plastics, Inc.?

There are many reasons to choose Applied Plastics, Inc. for your plastic tubing needs. We have over 50 years of experience in the industry, and our team is always available to help you select the right product for your application. We offer a wide variety of tubing products, and we’re always looking for ways to improve our products and services.

To find out more about what we can do for you, get in touch with us today!