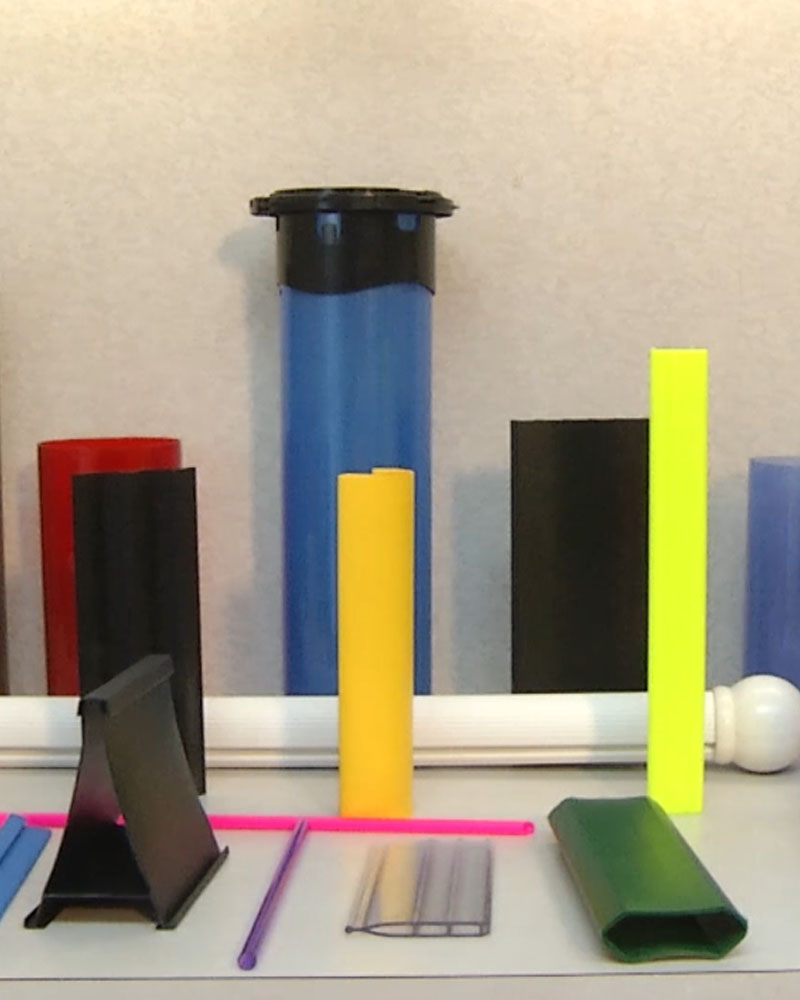

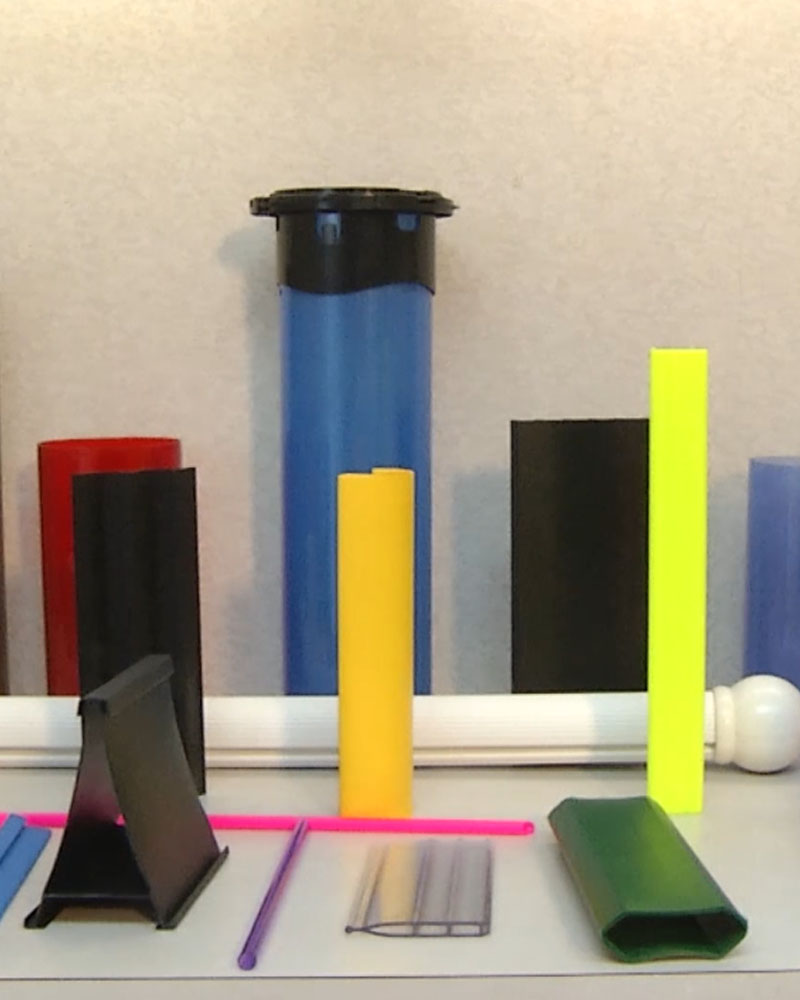

Custom Plastic Extrusion

With our 22 extrusion lines, we have the capabilities to manufacture extrusions for almost any application. We have produced tubing of all sizes up to 8″ diameter, and rigid or flexible profile shapes with wall sections up to 3/4″ thick.

Design Aid & Guidelines

Designing for “performance” will focus attention on the most important dimensions and tolerance and lead to a “cost efficient” profile product. Each plastic material has its own characteristics which require variations in the extrusion process. The shape and dimensions of a profile are more readily controlled in some plastics than in others. For this reason performance of the profile on the job must be the basic design consideration.

The dimensions and tolerances required should be established by considering how the profile will be used. The non-critical dimensions should be discussed with our engineers for recommendations on the most economical design.

Some of the questions which must be considered are:

- Is adverse applications environment a design criteria?

- Is it possible to design a totally “balanced” wall section?

- Can several small profiles be grouped into a common profile?

- At which point does the profile mate with other parts?

- How much will the mating parts vary?

- Do mating parts move relative to the profile?

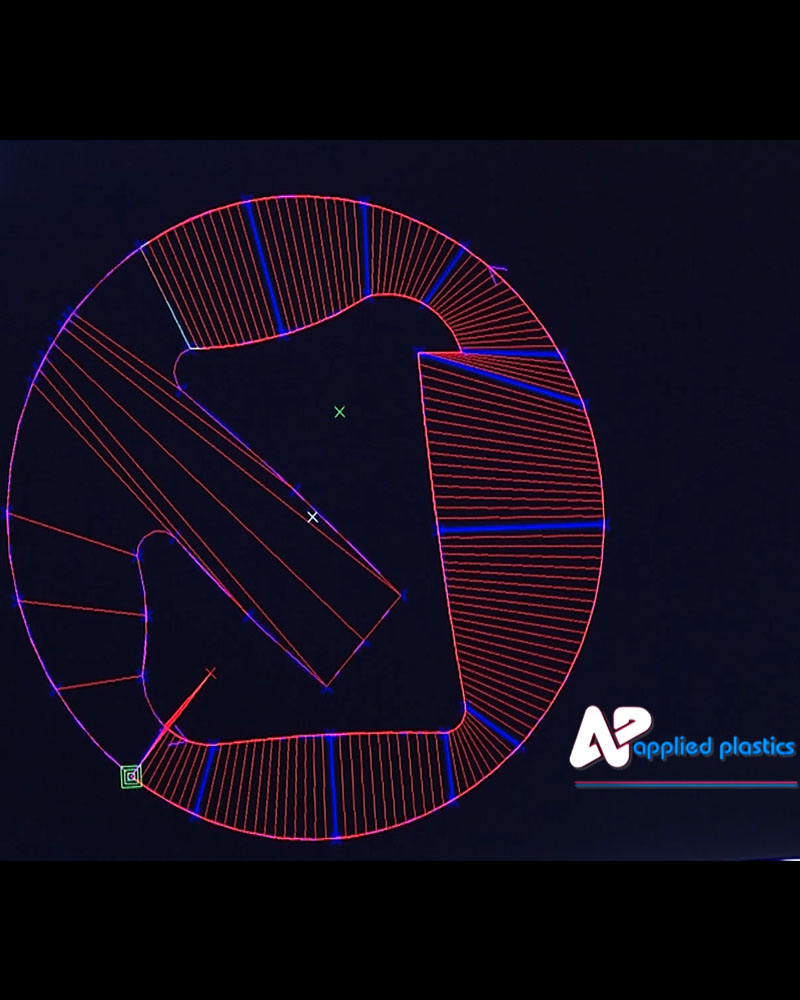

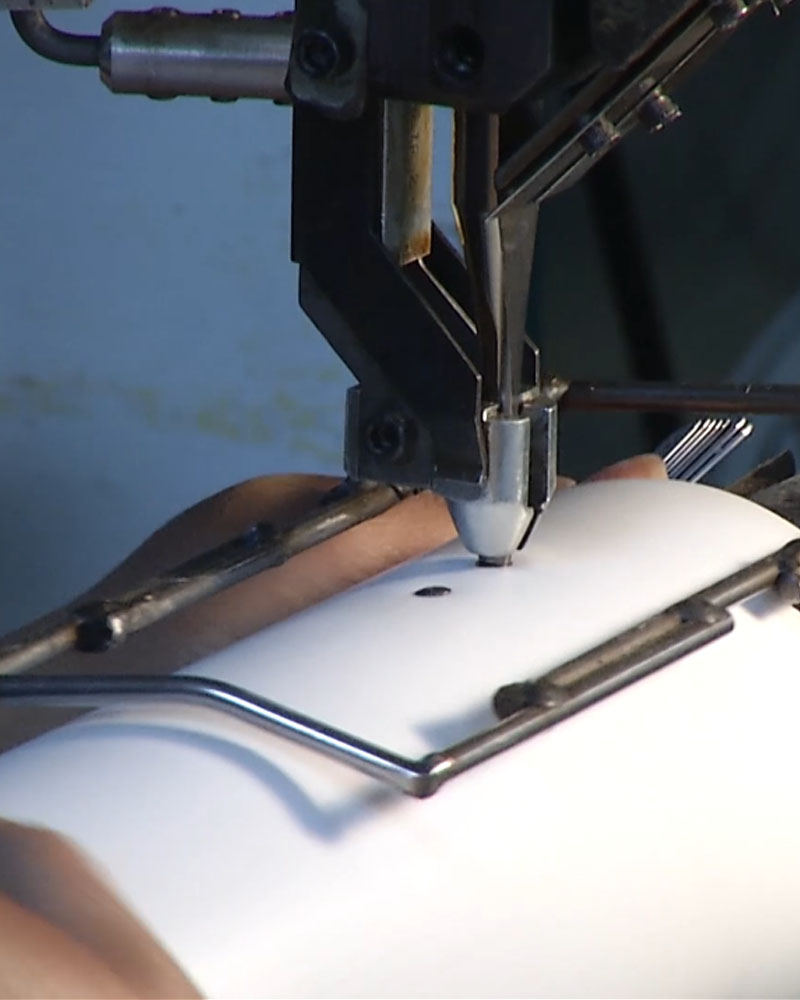

In House Tooling

Our in-house tooling department is unique in our industry. Here our skilled craftsmen produce top quality extrusion dies and downstream equipment to ensure that your parts are manufactured to your precise requirements. The result is shorter lead time and lower costs for the customer.

These tools are made possible by utilizing state of the art CAD software, coupled with our in-house wire EDM machining capabilities, enabling us to produce extremely complex and precise profile extrusions. Since all this work is done in-house, lead time is cut significantly and your product is manufactured sooner.

Warehouse

Our work doesn’t stop after we’ve completed a customer’s order. Applied Plastics will store the order in our warehouse, either in bulk, or in specialized packaging. We release a portion of the order to the customer, when they need it.

Inventory Management

Paramount in any extrusion project is lead time. Applied Plastics prides itself in minimizing lead time. Our over 40 years of experience in thermoplastic extrusions allows us to develop the necessary tools and materials in an efficient manner, getting product to your door quickly.

Cutting lead time on repeat orders is made possible with our large finished goods warehouse. This capacity enables us to offer our customers the opportunity to enter blanket orders with split shipment releases as their production needs dictate.

We also utilize a computer-based bar code system to facilitate our Just-In-Time and warehousing programs. This system allows us to accurately keep track of customer product, status and current inventory levels. Our customers depend on us to maintain accurate information and delivery schedules.