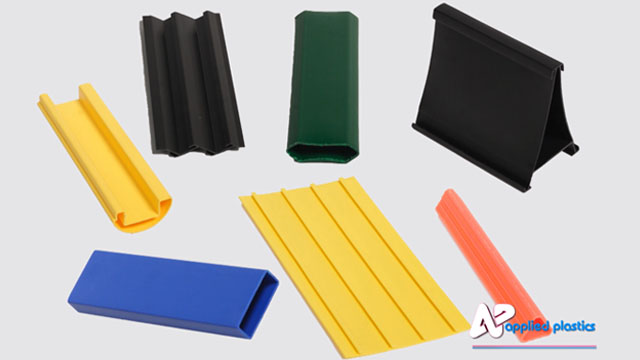

EXTRUSION CAPABILITIES

With our 22 extrusion lines, we have the capabilities to manufacture extrusions for almost any application. We have produced tubing of all sizes up to 8″ diameter, and rigid or flexible profile shapes with wall sections up to 3/4″ thick. We have co-extrusion capabilities for dual-durometer, and double and triple color combinations.

In addition to our tubing capabilities, we can produce solid rod with diameters up to 1/2″ in polyester, polypropylene, and polyethylene. Our experience provides us with the capability to develop solutions. We invite our customers to challenge us with special extrusion needs and difficult manufacturing problems.

Tubing

- Less than .062″ to almost 8″ diameter

- Wall thicknesses from under .010″ to .750″ or more

- Lengths from under .250 inch to over 30 feet/pc

- Custom colors

- Special packaging

Profile

- Up to 12″ wide

- Wall thickness from .015″ to .750″

- Lengths from .250 inches to 35 feet

- Clear to custom color match

- Commodity and engineering materials

Solid Rod

- Up to 1/2″ diameter

- Custom colors

- Special additives

- Available in polyester, polypropylene, and polyethylene

VALUE ADDED SERVICES

Whether inline or offline, our secondary operations might be the primary reason many companies choose Applied Plastics.

Providing total customer service means our work doesn’t end when your tubing or profile comes off the extrusion line. Applied Plastics offers a full array of value-added operations, allowing us to provide a finished custom part.

We’ll do just about anything our customer needs. Please inquire concerning your special needs. Some applications require purpose-built equipment. We are equipped to get your job done professionally, accurately, and on time.