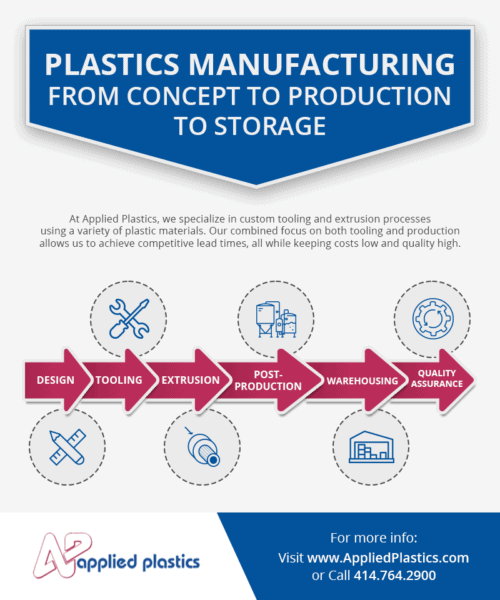

Plastics Manufacturing from Concept to Production to Storage

Leave a CommentWhen it comes to plastics manufacturing, extrusions are one of the most efficient means of producing components with continuous shapes, including tubes, pipes, profiles, and rods. The process uses heat and pressure to form shaved plastic into components of varying colors, textures, and sizes, and that have a range of physical and chemical properties. The tooling that enables such versatility is also economical, offering substantial cost-savings for high-volume production.

At Applied Plastics, we specialize in custom tooling and extrusion processes using a variety of plastic materials. Our combined focus on both tooling and production allows us to achieve competitive lead times, all while keeping costs low and quality high.

What Can our Extrusion Services Offer You?

Extrusion services offer a fast and economical way to create quality plastic components. Our primary capabilities include tubing, profiles, and solid rods in a range of sizes, materials, and colors.

- Our extrusion equipment accommodates hollow tubes as small as .062″ in diameter up to almost 8″ in diameter, with wall thicknesses from under .010″ to .750″ or more, and lengths from .250″ to over 30′. A variety of plastics, colors, and finishes are available to suit any tubing application, whether it be medical equipment, auto parts, fencing, or otherwise.

- For clients requiring custom shapes, we offer rigid or flexible profiles up to 12″ wide, with wall thicknesses from .015″ to .750″ and lengths ranging from .250″ to 35′. These profiles are ideal for products such as bumpers, covers, dividers, lenses, or trims, as well as a range of industrial assemblies. Our team creates tooling in-house for an economical approach to custom plastic products.

- Our solid polypropylene, polyethylene, and polyester rods are available in diameters up to 0.50″. Specialty additives increase durability and help components resist environmental hazards such as physical stresses or chemical exposures. Different compositions allow our rods to serve as bearings, gaskets, and seals across a range of industrial settings.

With over 22 extrusion lines and an extensive line of raw materials, we can create extruded parts for virtually any application.

A Guide to Plastics Design and Manufacturing

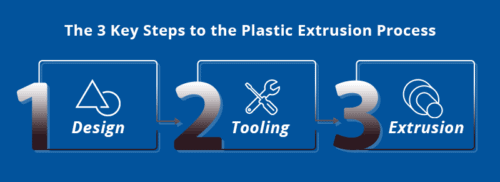

The plastic extrusion process is simple, fast, and cost-effective, although manufacturers must pay attention to some key constraints during the design process.

Design

As when designing any component for plastics manufacturing, engineers should begin the extrusion design process by considering the application’s constraints. For instance:

- Will the component be exposed to adverse conditions? If so, how often and what kinds?

- Where does this component mate with other parts, and what are the shapes and dimensions of those mating components?

- Do the mating components move during use?

The answers to these questions dictate the overall size and shape of the component, along with the ideal materials and additives for the application.

After determining the core design features, engineers can optimize for the limits and capabilities of extrusion. While extrusion can create a diverse range of profiles of almost any size, the most cost-effective products adhere to certain shapes and dimensions. When possible, designers should attempt to adhere to the following guidelines, which can speed manufacturing and improve part consistency:

- Wall sections should be as balanced as possible, with an even wall thickness throughout the design.

- When working with multiple small profiles, it may be beneficial to combine them into a single larger profile.

- Interior detailing on hollow components should be kept to a minimum.

- Radii should be as large as possible to prevent notching or cracking.

- Thermoplastics expand and contract during processing, so tolerances should be as lenient as allowable for the application.

The team at Applied Plastics can help evaluate your design for these and other criteria to ensure that extrusions proceed smoothly. Using CAD software, we create 2D and 3D models of the final components to give clients the best picture of how their design will turn out and to facilitate rapid modifications when necessary. Our experience-backed recommendations reduce lead times, cut costs, and improve part quality, making an already-efficient process even faster.

Tooling

After finalizing the design, your extrusion provider can begin to create tooling for your components. At Applied Plastics, we have over 60 years of experience in thermoplastic extrusion and manufacturing custom in-house tooling. We begin with the CAD drawings from the design process to determine the ideal tooling shape and identify any possible material interactions. We then use precision machining techniques to create custom tooling for the production process.

As part of our manufacturing process, we use wire electrical discharge machining (EDM) to cut through metal using a hot wire and electrode. EDM machining allows for precise forming of conductive metal parts, including complex shapes with tight tolerances. EDM machining also prevents rust, which preserves tooling and decreases costs for high-volume production runs.

Extrusion

The final step in the manufacturing process is the extrusion itself. We attach the custom die to an extruder machine, then load the chosen plastic materials into a hopper. The extruder melts the plastic, at which point a revolving screw pushes the molten material forward and through the die. This step forces the material to take on the desired shape. Finally, the plastic undergoes a controlled cooling process before any additional machining.

Post-Production Considerations

Plastic components are rarely ready immediately after forming, and extrusion is no different. To that end, we offer a full range of value-added services and post-production processing to ensure that our clients’ needs are met on time. Some common value-added services include:

- Cutting

- Drilling

- Punching

- Embossing

- Notching

- Slotting

- Assembly

We perform all of these services and more in-house and to our stringent quality standards, ensuring that clients receive production-ready components at a minimal extra cost and with no outsourcing. To learn more about how we maintain professional standards and competitive lead times via value-added services, contact us today.

Warehousing Services

At Applied Plastics, we understand the importance of minimizing lead time and consistently meeting client schedules. Our entire production process is optimized for efficient production and shipping. We maintain a stocked warehouse of finished goods to facilitate repeat or blanket orders, as well as a bar code system to track Just-in-Time product status. With our comprehensive tracking and warehousing services, we can ensure on-time delivery for orders of all sizes and complexities.

Quality Assurance

All of our core capabilities and value-added services for plastics manufacturing are subject to strict quality assurance procedures via our Total Quality Management program. Between custom design and tooling, part inspections, and comprehensive testing protocols, many of our clients have been able to cut inspections of their own. Our precise quality assurance protocols allow you to have complete confidence in our extrusion services.

Get in Touch with Us Today!

At Applied Plastics, we’ve spent decades honing our extrusion and machining processes, and we apply this expertise to custom tubes, rods, and profiles of all sizes. To learn more about how we can meet and exceed your expectations, contact our knowledgeable team today.